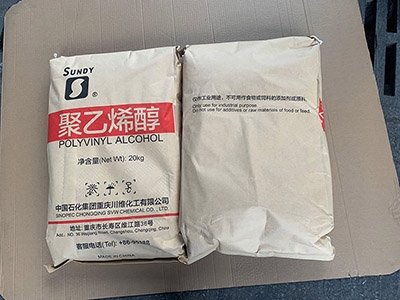

Polyvinyl Alcohol Sundy PVA

█ Polyvinyl Alcohol Sundy PVA

Sundy PVA stands for the preminium quality in China,also for Vinylon fiber, PVA fiber, Polyvinyl alcohol(PVA), Vinyl acetate monomer(VAM), Vinyl acetate-ethylene copolymer emulsion(VAE), and EVOH etc.

|  |  |

█POLYVINYL ALCOHOL (PVA)

PVA has many exceptional properties such as water solubility,fiber-forming property, adhesiveness, film-forming property, emulsionstability, dispersion stability, resistance to oil, acid, and alkali,chemical reactivity, biodegradability, as well as meltability (orthermoplasticity) and many unique and special properties throughmodification. PVA plant capacity has reached 160ktpa with more than 60categories. PVA is widely used in many industries like textile,papermaking, construction, chemicals, printing, packaging,pharmaceuticals, detergents & cosmetics, agriculture, ceramics, iron &steel, electronics, electrolysis, electroplating, and etc.

| Descriptions | Specification |

| Average polymerization degree | 200-3500 |

| Alcoholysis degree | 45%~100%(mol/mol |

| Residual Ac-≤ | 0.13% |

| Purity ≥ | 90% |

| Volatile ≤ | 8.00% |

| NaOAc ≤ | 2% |

| Viscosity | 3.0~110.0mPa∙s |

█ MAIN APPLICATIONS

In fiber fabrication

Two important applications of PVA is to be used as vinylon feedstockand sizing agent for textile.As raw material of vinylon fiber, has the advantages of being highin strength, moisture absorption, abrasion resistance, sunlightresistance, corrosion resistance and white in color. It can also be spunwith cotton, wool and viscose fiber or purely spun with itself.As sizing agent for textile, It will not corrode or deteriorate witha good adhesion to cotton, hemp, polyester and viscose fiber.

Pulp & PaperPVA has found wide use in the treatment of paper surface as it hasexcellent adhesiveness and dispersibility and will not affect the

property of other binders used in combination. The advantages of PVA using:Surface strength (printability);Strength along Z-axis(paper internalstrength);Folding resistance;Abrasive resistance; Improvedsmoothness;Improved surface glossiness;Raised resistance to oil andsolvent (barrier property).

Emulsion Stabilizer & Binder

PVA can be widely used as protective colloid or thickener for theemulsion polymerization of vinyl acetate (VAc) or VAc/ acrylate. has thefollowing characteristics: excellent adhesiveness;increased initial

tack and drying rate while used with filler;excellent resistance to oil;outstanding film strength;enduring and stable performance.

PVA can be used to produce water soluble film and water-resistancefilm. PVA is available in formed products which highlight the inherentfeatures of PVA, namely, high tensile strength, resistance to organic

solvent and air tightness.They are both widely used in the packageindustry, not only for textile, but also for chemicals, food, dailychemicals, agricultural chemicals, dyestuff, and etc.

Dispersion Stabilizer

PVA, which is excellent in colloid protection and has superior surfaceactivity, is often used as dispersion stabilizer for suspensionpolymerization of vinyl chloride monomer (VCM). The performance of PVC

resin can be greatly optimized by selecting a suitable PVA grade withproper degree of polymerization and hydrolysis.

| 主分散剂 | 醇解度% %(mol/mol) | 粘度( mPa.s) | 灰分( ≤wt.%) | 挥发份 (≤wt.% ) |

| FS-20 | 78.5-81.5 | 44.0-52.0 | 0.5 | 5.0 |

| FS-22H | 86.0-89.0 | 44.0-50.0 | 0.5 | 5.0 |

| FS-10 | 71.5-73.5 | 5.0-7.0 | 1.0 | 4.5-6.5 |

| 辅助分散剂 | 醇解度% %(mol/mol | 粘度 mPa.s | 固含量% | 外观 |

| FS-02 | 45.0-51.0 | 7.0-10.0* | 20±1 | 醇溶液 |

| FS-200 | 46.0-53.0 | 500-2000 | 39.0-41.0 | 水溶液 |

| FS-260 | 53.0-60.0 | 500-1500 | 38.0-40.0 | 水溶液 |

█PVA Specification

Sequence No. | New Standard Title | Hydrolysis mol/% | Viscosity mPa.s | Volatile (mpa.s) | Ash (wt%) | pH | Purity (wt%) |

| 1 | 088-03 | 87.0~89.0 | 3.0~4.0 | ≤5 | ≤0.5 | 5-7 | ≥93.0 |

| 2* | 098-03 | 98.0~99.0 | 3.5~4.5 | ≤5 | ≤0.7 | 5-7 | ≥93.5 |

| 3* | 088-04 | 87.0~89.0 | 4.0~4.5 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 4 | 098-04 | 98.0~98.8 | 4.0~5.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 5 | 088-05 | 87.0~89.0 | 4.5~6.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 6 | 098-05 | 98.0~99.0 | 5.0~6.5 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 7 | 088-07 | 87.0~89.0 | 6.5~7.5 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 8* | 088-08 | 87.0~89.0 | 8.0~10.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 9 | 098-10 | 97.0~99.0 | 8.0~12.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 10 | 098-08 | 98.0~99.0 | 9.0~11.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 11 | 100-10F | 99.0~99.7 | 9.0~11.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 12 | 088-13 | 87.0~89.0 | 12.0~14.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 13* | 098-15 | 98.0~99.0 | 13.0~17.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 14 | 093-16 | 92.5~94.5 | 14.5~18.5 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 15 | 088-17 | 87.0~89.0 | 15.0~19.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 16* | 098-20 | 98.0~99.0 | 18.0~22.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 17 | 080-22 | 79.0~81.0 | 19.0~25.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 18 | 080-20 | 87.0~89.0 | 20.5~24.5 | ≤5 | ≤0.7 | 5-7 | ≥93.5 |

| 19 | 092-20 | 91.0~93.0 | 21.0~27.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 20 | 094-27 | 94.0~96.0 | 22.0~28.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 21 | 096-27 | 96.0~98.0 | 23.0~29.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 22 | 100-27 | 99.0~ 100.0 | 22.0~28.0 | ≤5 | ≤0.7 | 5-7 | ≥93.5 |

| 23 | 098-27 | 98.0~99.0 | 23.0~29.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 24 | 100-27S | 99.8~ 100.0 | 23.0~29.0 | ≤8 | ≤0.7 | / | ≥90.0 |

| 25 | 088-26 | 87.0~89.0 | 24.0~28.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 26 | 095-28 | 94.0~96.0 | 26.0~30.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 27 | 097-29 | 96.0~98.0 | 27.0~31.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 28 | 098-30 | 98.0~99.0 | 28.0~32.0 | ≤5 | ≤0.7 | 5-7 | ≥93.5 |

| 29 | 088-35 | 87.0~89.0 | 29.0~34.0 | ≤5 | ≤0.3 | 5-7 | ≥93.5 |

| 30 | 092-35 | 91.0~93. | 30.0~36.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 31 | 100-35 | 99.0~100.0 | 35.0~43.0 | ≤5 | ≤0.7 | 5-7 | ≥93.5 |

| 32 | 098-39 | 98.0~99.0 | 35.0~43.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 33 | 100-40F | 99.0~100.0 | 37.0~43.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 34 | 100-40 | 99.8~100.0 | 35.0~45.0 | ≤8 | ≤0.7 | / | ≥90.0 |

| 35 | 080-35 | 79.0~81.0 | 32.0~38.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 36 | 088-40 | 87.0~89.0 | 38.0~42.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 37 | 098-45 | 98.0~99.0 | 42.0~48.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 38 | 080-44 | 79.0~81.0 | 40.0~48.0 | ≤5 | ≤0.7 | 5-7 | ≥93.5 |

| 39 | 084-48 | 83.0~85.0 | 42.0~54.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 40 | 088-50 | 87.0~89.0 | 45.0~55.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 41 | 092-53 | 87.0~89.0 | 48.0~58.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 42 | 097-60 | 96.0~98.0 | 56.0~66.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 43 | 098-60(G) | 98.0~99.0 | 58.0~68.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 44 | 100-60 | 99.0~ 100.0 | 58.0~68.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 45 | 088-60 | 86.0~87.0 | 50.0~58.0 | ≤5 | ≤0.7 | 5-7 | ≥93.5 |

| 46 | 097-70 | 96.0~98.0 | 66.0~76.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 47 | 100-70 | 99.0~ 100.0 | 68.0~78.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 48 | 098-75(G) | 98.0~99.0 | 70.0~80.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

| 49 | 098-78 | 98.0~99.0 | 73.0~83.0 | ≤5 | / | / | ≥93.5 |

| 50 | 100-78 | 99.8~ 100.0 | 73.0~83.0 | ≤8 | ≤0.7 | / | ≥93.5 |

| New grades | 080-03 | 78.5~81.5 | 3.0~4.0 | ≤5 | ≤0.5 | 5-7 | ≤0.5 5-7 ≥93.5 |

| 080-05 | 78~80 | 5.0~6.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 | |

| 085-03 | 84.0~86.0 | 3.0~4.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 | |

| -35 | 87.0~89.0 | 80.0~110.0 | ≤5 | ≤0.4 | 5-7 | ||

| SG-18I (Carboxyl modified PVA) | 96.0~99.0 | 25.0~32.0 | ≤5 | ≤2.0 | 5-7 | ||

| SG-182 (Carboxyl modified PVA) | 85.0~90.0 | 20.0~30.0 | ≤5 | ≤1.5 | 5-7 | ||

| 099-92 | 98.0~100.0 | 90~105 | ≤5 | ≤0.7 | 5-7 | ||

| RY-I | 86.0~89.0 | 4.0-4.5 | ≤5 | ≤0.5 | 5-7 | ≥93.5 | |

| RY-II | 86.0~89.0 | 4.5-6.0 | ≤5 | ≤0.5 | 5-7 | ≥93.5 | |

| RY-III | 87.0~89.0 | 20.5-24.5 | ≤5 | ≤0.4 | 5-7 | ≥93.5 | |

| RY-IV | 87.0~89.0 | 44~50 | ≤5 | ≤0.5 | 5-7 | ≥93.5 | |

| RY-V | 87.0~89.0 | 50~58 | ≤5 | ≤0.5 | 5-7 | ≥93.5 |

Remark: The darkening part with sequence No.* is compliant with new national standard GB/T12010.3-2010, the other part is in accordance with new enterprise standard Q/SH 1115 105--2012.